High performance in a compact package

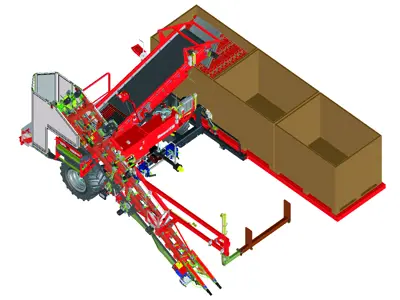

The P3K Profi is a mounted 1-row top lifting harvester with a wide 3-piece discharge elevator. This elevator guarantees maximum capacity and minimum drop height. Thanks to the separate sieving conveyor below the knives, the discharge elevator can always be filled optimally, with care for product-friendliness.

The heart of a Dewulf top lifting harvester

The top lifting harvesters produced by Dewulf are made with high-quality, wear-resistant standard components. The bearings of each cutters set is hermetically sealed using ‘Labyrinth Sealing’. This provides the highest degree of durability available on the market. Each cutters set is driven by a maintenance-free ‘Gearbox Drive’: two heavy-duty pinions ensure perfect synchronisation of the knives.

Working with pleasure means working faster

The intuitive operating console makes working with a mounted top lifting harvester from Dewulf particularly enjoyable. The console was specially designed to enable the user to harvest a perfect product with a minimum of operations. Pictograms make it easy to see which function is available and ready for use. The operating console communicates via CANBUS for the Profi models. To make operating the discharge elevator even easier, you can opt for a wireless remote control or a keypad by the sorting platform.

Also available with sieving belt unit

The P3K Profi is also available with a sieving belt unit instead of the standard lifting belt unit. This so-called 'winter channel' is extremely suitable for harvesting harvesting potatoes, or root crops of which the foliage is no longer strong enough to be gripped by a lifting belt, for example due to the weather conditions.

- ■ = standard

- o = Optional

- - = Not applicable

| Harvesting unit | ||||||

| Length of the harvesting belts [mm] | 8000 | |||||

| Share protection with shear bolt | o | |||||

| Torpedoes | ■: fixed / o: rotary | |||||

| Synchro Flow | o | |||||

| ADC (Automatic Depth Control) | o | |||||

| Automatic hydraulic belt tensioners | o | |||||

| Hydraulically driven roller below cutters | o | |||||

| Harvesting share for red beet or celeriac | o | |||||

| Width of cross conveyors [mm] | 610 | |||||

| Sieving harvesting unit instead of harvesting belt unit | o | |||||

| Sorting platform | o | |||||

| Cleaning | ||||||

| Rotary cleaners below the harvesting belts | o | |||||

| Hydraulic duo agitator in the cross conveyor | o | |||||

| Discharge elevator | ||||||

| Width [mm] | 800 | |||||

| Discharge height [mm] max. | 4000 | |||||

| Loading chute at the end of the discharge elevator | o | |||||

| Tractor | ||||||

| Minimum tractor power [hp] | 80 | |||||

| PTO drive shaft | 540 rpm | |||||

English

English

Nederlands

Nederlands

Deutsch

Deutsch

Français

Français

Polski

Polski

Espagnol

Espagnol

русский

русский